ITD Tech Tips - Bolt-On Spindles

Jul 9th 2020

Tech Tips – Bolt-On Spindles

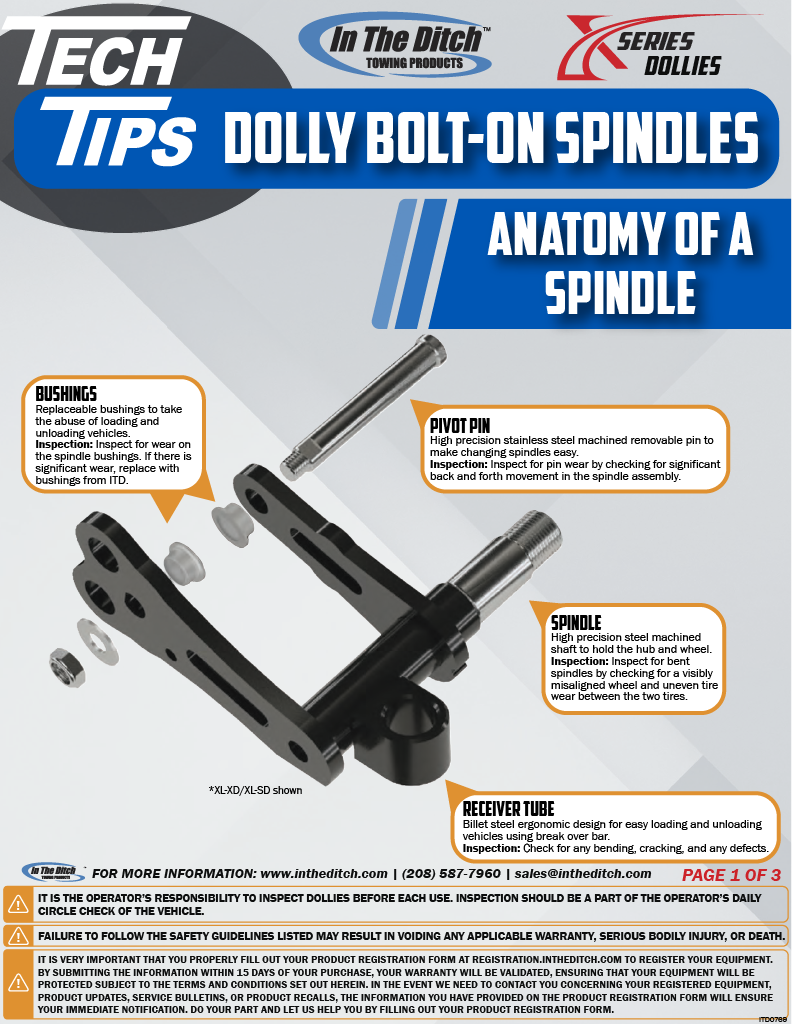

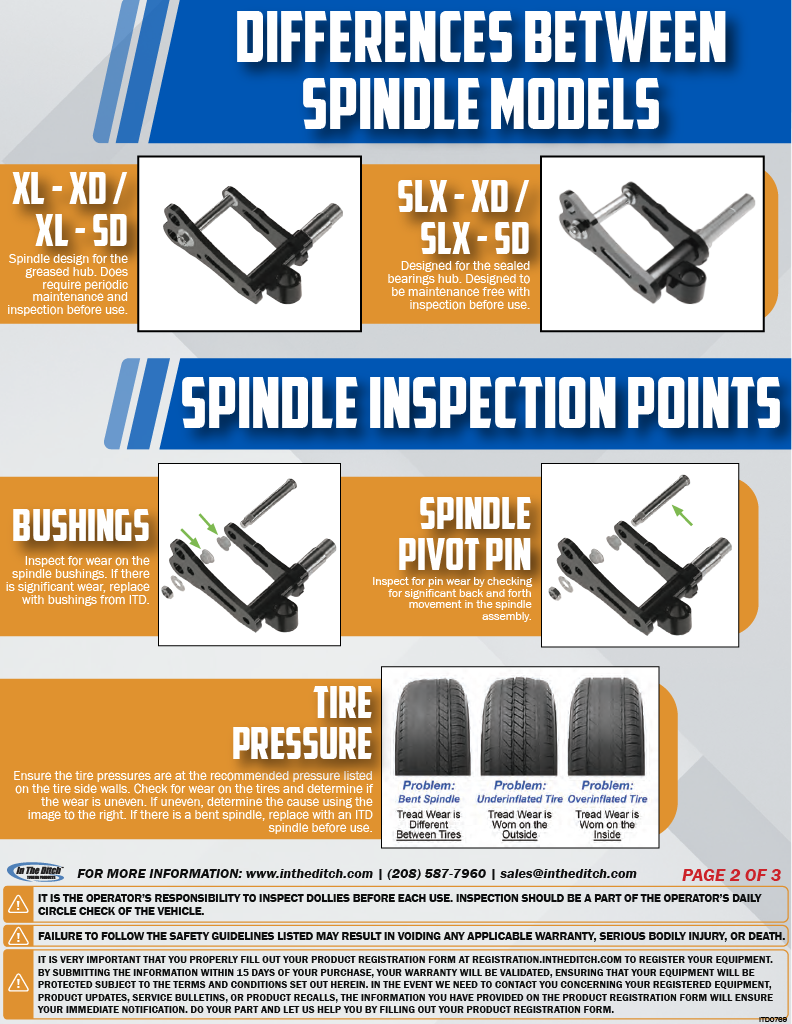

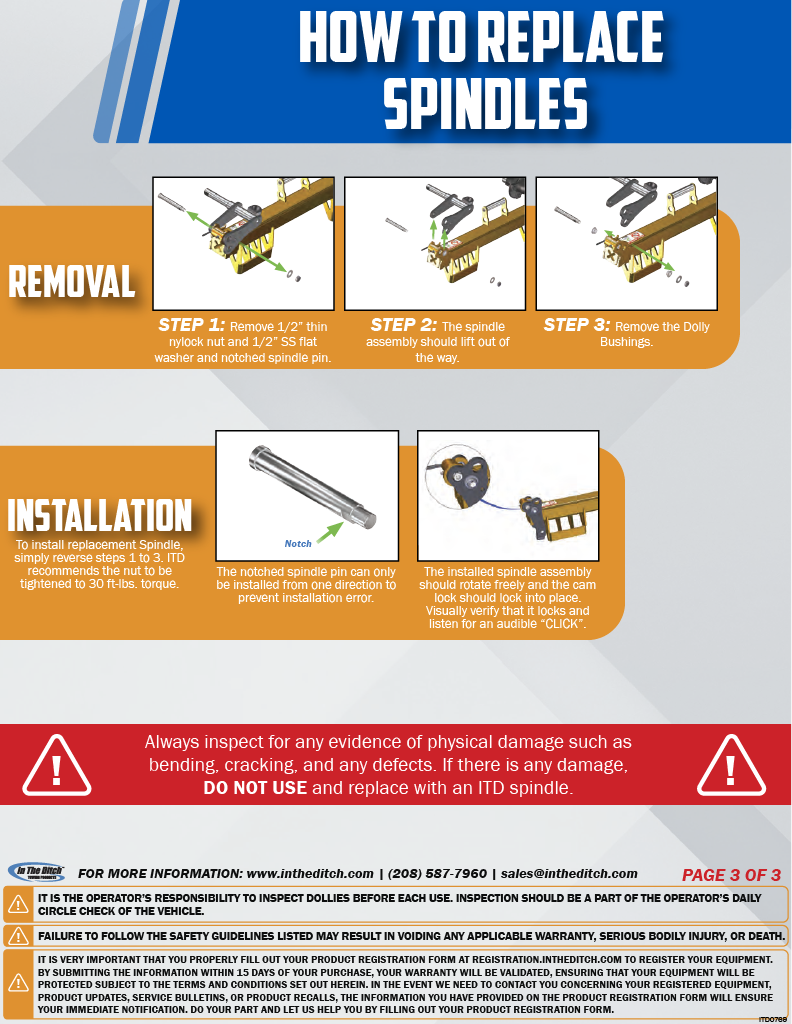

In-The-Ditch’s new X-Series dollies feature a bolt-on, easy to replace spindle assembly with high wear durable bushings standard. The Speed Lube spindle allows grease to enter the center of the spindle with a standard grease gun. It forces new grease into the spindle, pushing the old grease forward, then exiting the spindle. Without the mess, this completely repacks the bearing with new, clean grease. The spindle assembly comes powdercoated from the factory in one of four models. The XL-XD and XL-SD spindle designs are for the greased hub and require periodic maintenance and inspection before use. The SLX-XD and SLX-SD spindle designs are for the sealed bearings hub and designed to be maintenance free with inspection before use. This useful tech tips guide from In The Ditch breaks down the anatomy of the new spindles showing details about the replaceable bushings, pivot pin, high precision spindle and the billet steel receiver tube and inspection tips for each. Specific points to remember when inspecting the Bolt-On spindles are included as they pertain to the bushings, pivot pin and tire pressure. And finally, In The Ditch details the steps involved in replacing these spindle parts.