Care and Maintenance of Wire Rope Winch Cable

Posted by Tim Ryan on Jan 2nd 2024

Proper care and maintenance of a wire rope winch cable are crucial to ensure the safety and longevity of the equipment. Here are some guidelines to help you maintain a wire rope winch cable:

1. Regular Inspection -

Visual Inspection:

- Regularly

inspect the entire length of the wire rope for any signs of damage, such

as kinks, broken wires, or deformation.

- Look for corrosion or rust, especially in areas with exposure to harsh environments.

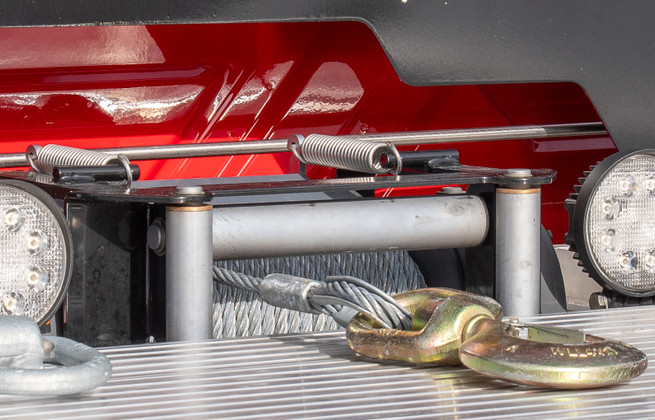

End Connections:

- Examine

end connections, such as hooks and thimble, for any signs of wear,

deformation, or damage.

- Ensure that the connections are secure and properly fitted.

2. Cleaning -

Dirt and Debris:

- Remove

dirt, mud, and debris from the winch cable regularly, as these can

accelerate wear and corrosion.

- Use a brush or compressed air to clean the strands and remove contaminants.

Corrosion Prevention:

- Apply

a corrosion inhibitor or lubricant to the wire rope to protect it from

rust and corrosion.

- Ensure that the lubricant is suitable for the specific conditions in which the winch is used.

3. Lubrication -

Proper Lubrication:

- Regularly

lubricate the wire rope to reduce friction and prevent wear.

- Use a lubricant specifically designed for wire rope and follow the manufacturer's recommendations.

Inner Strands:

- Pay attention to the inner strands of the wire rope when applying lubricant to ensure thorough coverage.

4. Tension and Alignment -

Proper Tension:

- Maintain

proper tension in the wire rope to prevent slack, which can lead to kinks

and damage.

- Follow the manufacturer's guidelines for the recommended tension.

Alignment:

- Ensure that the wire rope is properly aligned on the winch drum to prevent uneven loading and premature wear.

5. Usage Guidelines -

Avoid Overloading:

- Do

not exceed the recommended load capacity of the winch or wire rope.

- Avoid sudden jerks or shock loading that can cause damage.

Proper Spooling:

- Spool the wire rope evenly on the winch drum to prevent overlapping and uneven winding.

6. Storage -

Dry Storage:

- Store

the wire rope in a dry, clean environment to prevent corrosion.

- Elevate the reel off the ground to avoid contact with moisture.

Protection from Elements:

- Protect the wire rope from exposure to harsh weather conditions when not in use.

7. Record Keeping -

Maintenance Log:

- Maintain a log of inspections, lubrication, and any maintenance activities performed on the winch cable.

Replacement Schedule:

- Establish a schedule for replacing the wire rope based on usage and wear.

Regular and thorough maintenance will not only extend the life of the wire rope but also contribute to the overall safety and efficiency of the winch system. Always refer to the manufacturer's guidelines and recommendations for specific maintenance procedures and intervals.

What sizes do wire ropes come in?

The new industry standard, and what ECTTS carries is 6 x 25, which is stronger than the old version, 6 x 19, used to be. Wire ropes for winch cables are also made in 6 x 37 and 6 x 35, which are bigger cables with more strands for heavy wrecker needs.

What do these numbers mean?

Wire rope is made up of the core and the strands.

The core runs through the center and is either made of fiber or steel. Steel core also has a steel wire that can be another strand or a separate section of wire rope.

A strand is several wires twisted together, used by itself or made into a thicker cable when combined with other strands. Hence where the name wire rope comes from.

Strands times wires per strand plus core type is how one orders a wire rope, so 6 x 25 means that there are 6 strands with 25 wires per strand surrounding the core, which can be either fiber core or steel core, depending on your needs and the features each core type offers that suit the job you need the wire rope for.

Wire rope is made in your choice of:

Fiber Core gives you greater working flexibility and is not prone to kinking.

Steel Core offers more strength, made with galvanized steel.

Both Fiber Core and Steel Core are corrosion-resistant.

Click here to see sizes and options of winch cable wire rope.